|

Microcyber Corporation

|

high precision digital differential pressure transmitter

| Price: | 360.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Liaoning, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

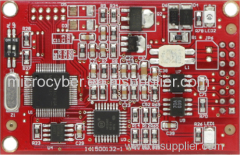

NCS-PT105II series pressure transmitter with capacitance sensor is available on FF H1, Profibus PA and HART protocols. The Transmitter has high accura

Brief Introduction

As a new generation of s high presicion Profibus PA protocol differential pressure transmitter mart fieldbus pressure transmitter, NCS-PT105II series pressure transmitter with capacitance sensor is available on FF H1, Profibus PA and HART protocols. The Transmitter has high accuracy, better reliability and intrinsically safety.

1.Excellent performance:

High accuracy: ±0.075%(20°C, range rate 10:1)

Stability: ±0.1% of maximum range per year

High range rate: 100:1

2.Multi sensor: differential pressure (SD), high static pressure (SH), gauge pressure (SG), absolute pressure (SA), micro differential pressure (SR)

3.Compensation: automatically environmental temperature compensation

Figure

intelligent gauge pressure transmitter Size (Unit: mm)

Transmitter Installation

The Connection of the Smart Transmitter

Basic Parameter

Measure object | Liquid, gas, stream | |

Power | 9~32V DC(FF,PA) 9~32V dc (FF, PA Explosion-proof instrument) 11.9~42 V DC (HART) 11.9~30 V DC (HART Explosion-proof instrument) | |

Output | Analog: 2 wire 4~20mA Digital: HART, FF and PA signal | |

Load resistant | 0~1500ohm (common) 250~550ohm (with HART) | |

Insulation | Input and output insulating voltage: 500Vrms (707VDC) | |

Display | Optional 6 bits digital number or 5 bits characters LCD display | |

Temperature scale | Work temperature: -40 - 85°C (No display) -30 - 70°C (display) -30 - 60°C (Explosion-proof) Store temperature: -40 - 100°C (No display) -40 - 85°C (display) | |

Allowed media temperature measured | -40 °C - 110 °C (Type name include 'IC') -40 °C - 149 °C (silicone oil) -40 °C - 204 °C (sylthlem800) -18 °C - 204 °C (inert liquid) -40 °C - 104 °C (others) | |

Humidity scale | 5%-100%RH | |

Start time | ≤ 5 seconds | |

Refresh time | 0.2 seconds | |

Dump adjusting | Time constant 0-15 seconds | |

Change of cavity | < 0.16 cm3 | |

Static pressure limit | SR | Range 2: 1000psi (6.89MPa) |

SD | Range 3-8: 2000psi (13.8MPa) | |

SG | Range 3-8: 2000psi (13.8MPa) Range 9: 4500psi (31.0MPa) Range 0: 7500psi (51.7MPa) | |

SA | Range 4: 58psi (400kPa) Range 5: 218psi (1500kPa) Range 6: 435psi (3000kPa) | |

SH | Range 4-7: 4500psi (31.0MPa) | |

wide range rate high accuracy gauge pressure transmitter Performance Index

Precision | For range 2 ±0.1% of Span is for 0.5 URL≤Span ≤ URL; ±[0.05+0.025 ×(URL / Span)]% of Span is for Span<0.5 URL. For other ranges ±0.075% of Span is for 0.1 URL≤Span ≤ URL; ±[0.025+0.005 ×(URL / Span)]% of Span is for Span<0.1 URL |

Temperature effect | Total effects per 28°C(50°F)change: For range 2 ±[0.05% URL +0.25% Span] For other ranges Span≥0.1 URL: ±[0.019% URL +0.125% Span] Span<0.1 URL: ±[0.025% URL +0.125% Span] |

Long time stability | In 12 months, ±0.1% of maximum range |

Static pressure effect | For range 2 ±1% / 13.8MPa For range 3 ±0.5% / 13.8Mpa For other ranges ±0.25%/13.8MPa |

Location installed effect | The maximum of the zero point movement is 0.24kPa |

Power effect | < 0.005%/V of range calibrated |

Explosion-proof | intrinsically safety Ex ia II C T4 |

Explosion-proof level | IP65 or IP67 |

Vibration effect | Meet GB/T 2423-1995 |

Electromagnetic compatibility | Meet GB/T 17626-1998 (IEC 61326-1:1997) |

Physical Properties

Electrical connection | 1/2-14NPT thread in. |

Process connection | 1/4-18 NPT thread in. |

Drawing pressure connector | Range 2~5, distance of center is 2.122 inch (53.9mm) Range 6, distance of center is 2.176 inch (55.3mm) Range 7, distance of center is 2.197 inch (55.8mm) Range 8, distance of center is 2.236 inch (56.8mm) Range 9, distance of center is 2.260 inch (57.4mm) Range 0, distance of center is 2.291 inch (58.2mm) |

Structural materials | Isolated Membrane and exhaust/outlet valve: 316 stainless steel Flange and connector: 316 stainless steel O-ring: fluororubber Filled liquid: silicon oil or fluorocarbon oil Bolt: zinc plating carbon steel (the material above should be selected at order, if has other requirement, please report in advance) Housing: low copper of albronze Coating: dion epoxy resin |

Height | Display type: 3.5kg No display type: 3.3kg |